Project Overview

The Perry Wastewater Treatment Facility was originally constructed in 1964 with major upgrades completed in 1967, 1987, 1993, and 1998. Most components of the current facility have been in service for more than 25 years, exceeding the expected lifespan of 20 years. Today, the plant requires repair and renovation in order to remain in compliance with current and new DNR regulations and to continue discharging high quality effluent to the North Raccoon River. The following is a brief overview of items that will be addressed in the upcoming improvements project:

Project Details

Preliminary Treatment Building

|

Water enters the treatment facility through the gravity sewer at the Preliminary Treatment Building. A mechanical screen removes large solids from the water that could plug piping and cause problems downstream in the treatment process. Grit is removed to help protect pumps. Corrosive sewer gases are released in the building and can shorten the life of equipment. The Preliminary Treatment Building is over 25 years old and requires renovation and replacement of air handling and wastewater process equipment.

|

New Anoxic Basin

|

A discharge goal of 10 mg/L Total Nitrogen will be required by the Iowa Nutrient Reduction Strategy in the near future. Nitrogen removal will be accomplished by providing ideal conditions for the biological conversion of Nitrate that is formed in the Aeration Basins to Nitrogen gas which is released to the atmosphere. A new concrete tank with mixing equipment will be constructed to carry out this process. A system for recirculating high nitrate concentration wastewater from the Aeration Basins will be installed.

|

Aeration Basins

|

In the Aeration Basins, ideal conditions are created for the aerobic bacteria (bacteria that need oxygen) to grow and eat the waste (CBOD) present in the water. Bacteria also convert Ammonia to Nitrate. Air from the Blowers is piped to the bottom of the basins and released in the water as small bubbles through devices called diffusers. Over time, diffusers plug and require cleaning or replacement. The existing ceramic diffusers are 25 years old and will be replaced with lower maintenance membrane diffusers.

|

Blowers

|

The Blowers provide air to the Aeration Basins and Aerobic Digesters. Air provided to the Aeration Basins is critical to the treatment of wastewater. Air provided to the digesters and storage tanks provides mixing and allows further breakdown of biosolids. The blowers operate like large fans that compress the air and move large volumes of air through the pipes to the wastewater tanks. The existing blowers are over 20 years old and will be replaced with more efficient units that are designed to meet future air requirements.

|

Chemical Phosphorous Removal

|

A discharge goal of 1 mg/L Total Phosphorus will be required by the Iowa Nutrient Reduction Strategy in the near future. Phosphorus removal will be accomplished by iron or aluminum chemical addition with intensive mixing at a new Rapid Mix Basin. Solid particles of phosphorus containing material will be formed in the Rapid Mix Basin and settled out in the Clarifiers along with the biosolids.

|

Clairifiers

|

The Clarifiers follow the Rapid Mix Basin and Aeration Basins. After the waste is consumed by the bacteria in the Aeration Basins, the treated wastewater flows by gravity to the Clarifiers. In the Clarifiers the bacteria (activated sludge) settles to the bottom of the tank where it is removed and returned back to the Aeration Basins to consume more waste. A portion of the bacteria is pumped to storage tanks each day and will eventually be spread on agricultural fields as nutrient rich fertilizer. Once the bacteria is settled out, the clear liquid from the top of the Clarifiers will be pumped to UV Disinfection.

Clarifer mechanisms are over 20 years old and will be replaced. An additional clarifier will be constructed to comply with State Design Standards. |

Biosolids Handling and Storage

|

The bacteria in the Aeration Basins convert waste to energy and grow in population. Each day excess biomass (bacteria) is pumped from the Clarifiers to the Aerobic Digesters where the bacteria further degrade before being pumped to the Biosolids Storage Tanks. Pumps and mixing equipment need to be renovated and replaced due to age of the equipment.

|

UV Disinfection

|

The City’s discharge permit requires plant effluent to be disinfected prior to discharge to the North Raccoon River. Ultraviolet light emitted from light bulbs submerged in the channel disinfect the water flowing past. Water then flows by gravity to Beaver Creek and North Raccoon River.

The existing UV system electrical equipment has extensive corrosion and system replacement is required. A new channel will be constructed at grade to help prevent damage to the system from flooding. |

Electrical and Controls

|

Electrical and Controls systems are a vital part of the treatment plant. The equipment is over 20 years old and service is difficult with limited replacement parts available.

Electrical equipment generates heat and excessive heat can damage the equipment. The existing electrical room is not air conditioned and panel doors must be left open to prevent overheating in the summer. Electrical equipment will be replaced and air conditioning installed to protect and extend the life of the new equipment. |

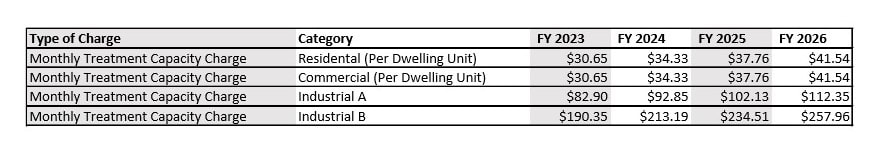

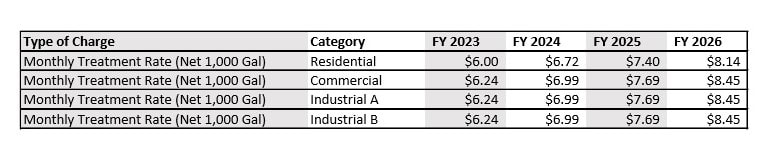

Rate Adjustments

Sewer Availability Rates - Effective July 1, 2022

Sewer Usage Rates per 1,000 Gallons - Effective July 1, 2022

Project Updates

Project Timeline

- Apply for SRF Planning and Design Loan- Fall 2018

- Submit Facility Plan and SRF IUP Application- Fall 2018

- CDBG Grant Application- Dec 2018

- Design- Winter 2018-19

- Submit DNR Construction Permit Application- Jan 2019

- Notice To Proceed- March 2019

- Construction Continues - Summer 2022